Thermit® News July 2022

THERMIT® NEWS

JULY 2022

|

THERMIT®

Simpler handling with the Thermit® weld

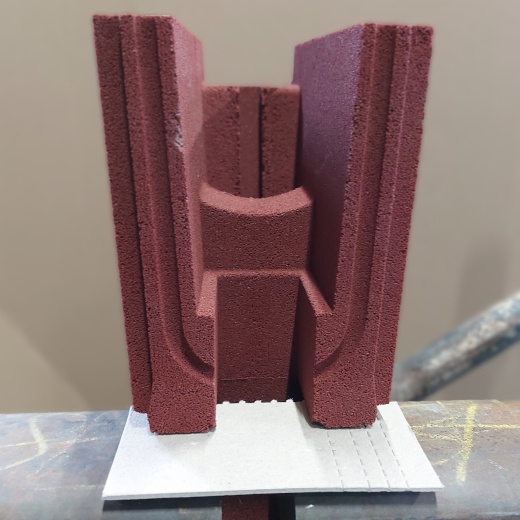

We have further developed the cardboard blanks to cover the running surfaces for the SoW-5 and SkV-Elite L29 processes to improve the safety and reliability of the Thermit® weld and simplify handling.

Instead of the current cardboard blank variants for covering the running surface, in future there will be only one adjustable blank. The corrugated boards have been replaced with a thick and more stable hardboard. Perforated lines allow the blank to be adjusted to suit the profile, making it suitable for sealing with sand or paste. The separating boards in the molded carton are still made of corrugated board, but have been optimised in terms of size and perforations, and can be used for welds with worn rails.

Changing the cardboard has improved the quality of the Thermit® weld further still. As proven by laboratory testing in Elektro-Thermit's welding shop and test welding at customer premises in Belgium, Austria, Sweden, and Switzerland.

The switch to the new cardboard blanks commenced in July 2022. If you have any questions, please contact your sales representative.

TRADE FAIR

Goldschmidt showcases products and services at three trade fair booths

Five years after the last trade fair in Münster, the time had come again to meet the public. The iaf trade fair welcomed 12,000 visitors and 140 exhibitors from 31 May to 2 June.

This year Goldschmidt attended with three booths focused on our products and services from the Rail joining, Inspection solutions and Road-Rail vehicles divisions. A bogie fitted with different sensors that graphically presented the range of the inspection solutions portfolio attracted significant attention from visitors. The outdoor booths with our road-rail vehicle and exhibits from the Original Thermit® and Insulated Rail Joints divisions and live demonstrations of our Thermit® welding process also recorded strong visitor numbers. Overall the trade fair was a complete success and we look forward to attending the InnoTrans in September.

NETHERLANDS

External training site

Following a successful final audit, an external welding training centre in the Netherlands was recognised by Elektro-Thermit in April.

This audit was preceded by a request from ProRail B.V., the Netherlands' largest railway infrastructure operator, to establish a training centre to host theoretical and practical basic training and upgrades to Thermit® welders. The companies VolkerRail, Strukton and Almar Railinfra worked together on this project.

To ensure the high quality standards of Elektro-Thermit in this division, future training staff from VolkerRail, Strukton and Almar Railinfra and the training workflows were extensively audited by Elektro-Thermit.

Thanks to this new cooperation, we can now offer you an even more comprehensive and more effective service for training Thermit® welders.

PRACTICAL TRAINING

Working instructions for the Thermit® welding method

The processing of our consumable materials by your trained employees to create a high quality finished product must be performed in accordance with the latest version of our work instructions.

A complete overview of our work instructions, sub-divided according to language and methods, is available here. Your contact in the Technical Service or Sales departments will be happy to provide you with the requested version of the work instruction you require.

CAREER

Become part of our team

As an international employer in the rail industry, we offer varied crisis- and future-proof jobs.

Our products and our expertise can be found in almost all rail networks worldwide. As a world-leading provider for Thermit® welding, we also offer many other products and services for modernising and maintaining rail networks. We are part of the Goldschmidt group — an innovative, modern and global group of companies that can count over 20 sites worldwide.

We offer varied and long-term prospects for both career starters and experienced hires. Become part of our team.

Go to the vacancies here.

|

For comments or questions, please contact:

Manuela Illmer

manuela.illmergoldschmidt.REMOVE-THIS.com

Editor:

ELEKTRO-THERMIT GMBH & CO. KG

A GOLDSCHMIDT COMPANY

Chemiestr. 24

06132 Halle (Saale), Germany

Managing Directors:

Dr.-Ing. Matthias Wewel

Dr.-Ing. Axel Hoeschen

Editorial (v.i.S.d.P.):

Manuela Illmer

E-mail: manuela.illmergoldschmidt.REMOVE-THIS.com

Tel.: +49 345 7795-718

VAT Reg. No.: DE 203131971

Tax No.: 110/112/02561

Registration office: Stendal

Registration number: HRA 34021